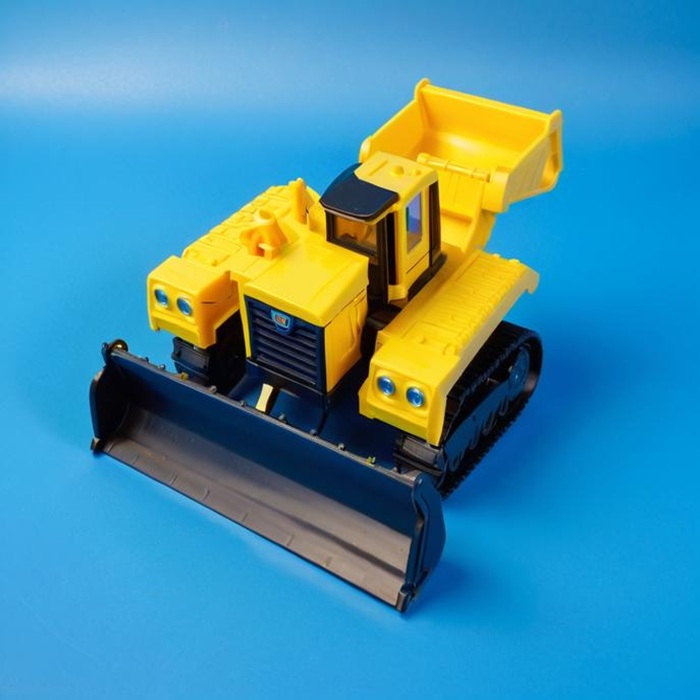

Pushing Powder Robot

Pushing Powder Robot is an automated equipment dedicated to the maintenance of ship and petrochemical

tank facades. It achieves stable movement of vertical and curved surfaces through magnetic adsorption or

vacuum wall attachment technology, and can integrate functional modules such as rust removal, spraying,

and detection. It is suitable for high-risk operation scenarios such as tank outer walls and ship structures.

Its core value lies in replacing manual completion of surface treatment and safety monitoring tasks in

high-altitude, flammable and explosive environments, and promoting the transformation of operation

and maintenance processes towards unmanned and standardized operations.

Application scenarios:

Petrochemical storage tanks:

External wall maintenance work:

High pressure water jet is used to remove rust and residue on the outer wall of the tank, with a daily treatment area

of 60-80 square meters and a wastewater recovery rate of ≥ 95%.

Post weld treatment:

The mechanical removal unit is paired with a flexible polishing head, achieving a burr removal efficiency of 8-12m/h

for weld seams and reducing roughness to Ra ≤ 6.3 μ m.

- Previous:Wind Turbine Tower Robot